Engineering

Ochre

A fully functional, machined citrus press juicer in 8 weeks

Project Details:

Individual project in an introductory machine shop class (2015)

Objectives:

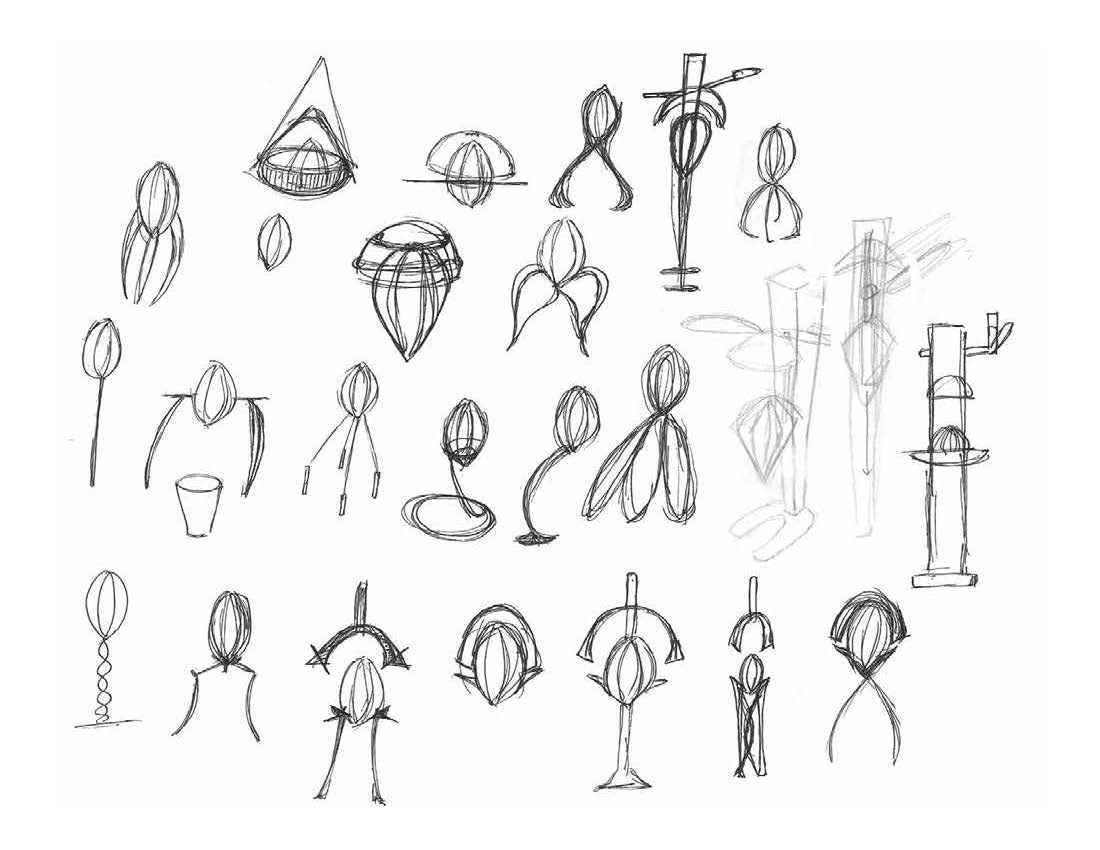

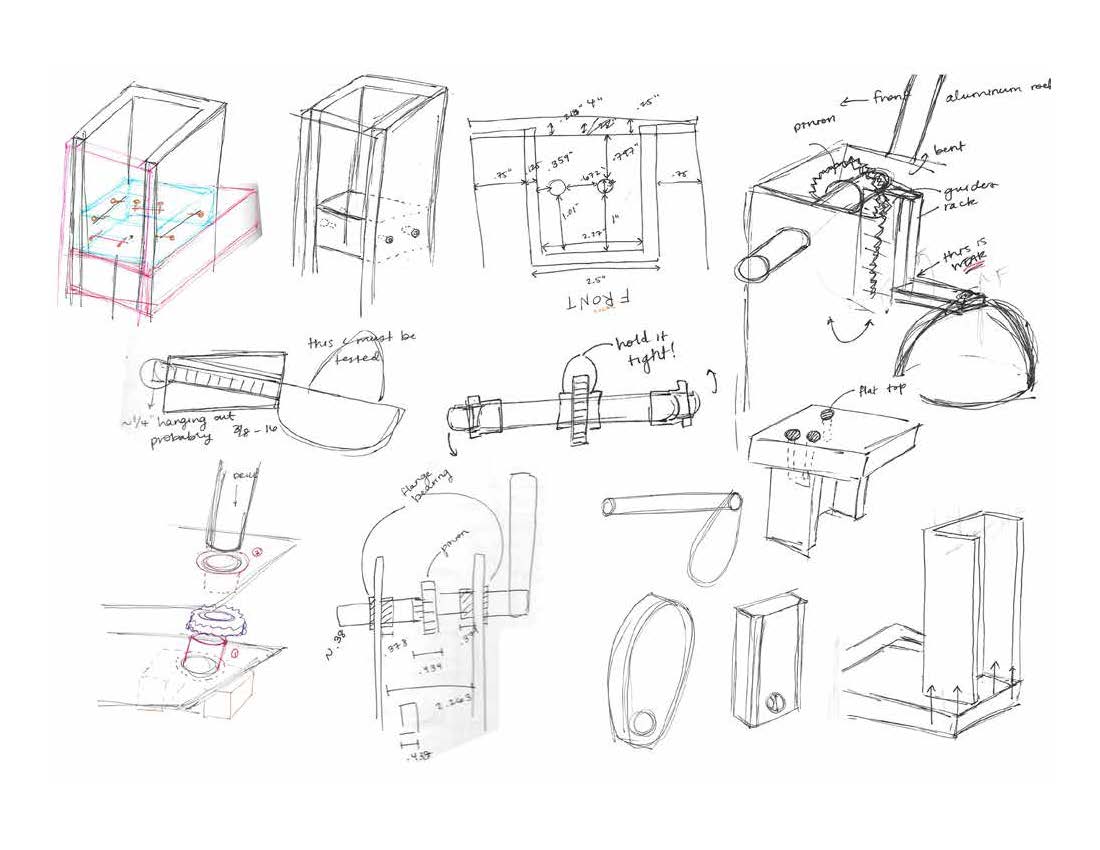

This started as an aesthetics-driven project with the goal of emulating Philippe Starck’s Juicy Salif, but ultimately I had to compromise on the vision in order to meet time and functionality constraints. The built product had to be functional, but anything approximating Starck’s fluid form that could juice a real orange required a core mold–interestingly enough, later I learned he was fully aware that his juicer was not very functional.

Given the multitude of moving parts, time limits on machine shop time, and my lack of experience, I opted to change my design to include a rack-and-pinion press, focusing the user experience on ergonomics rather than beauty.

Outcome:

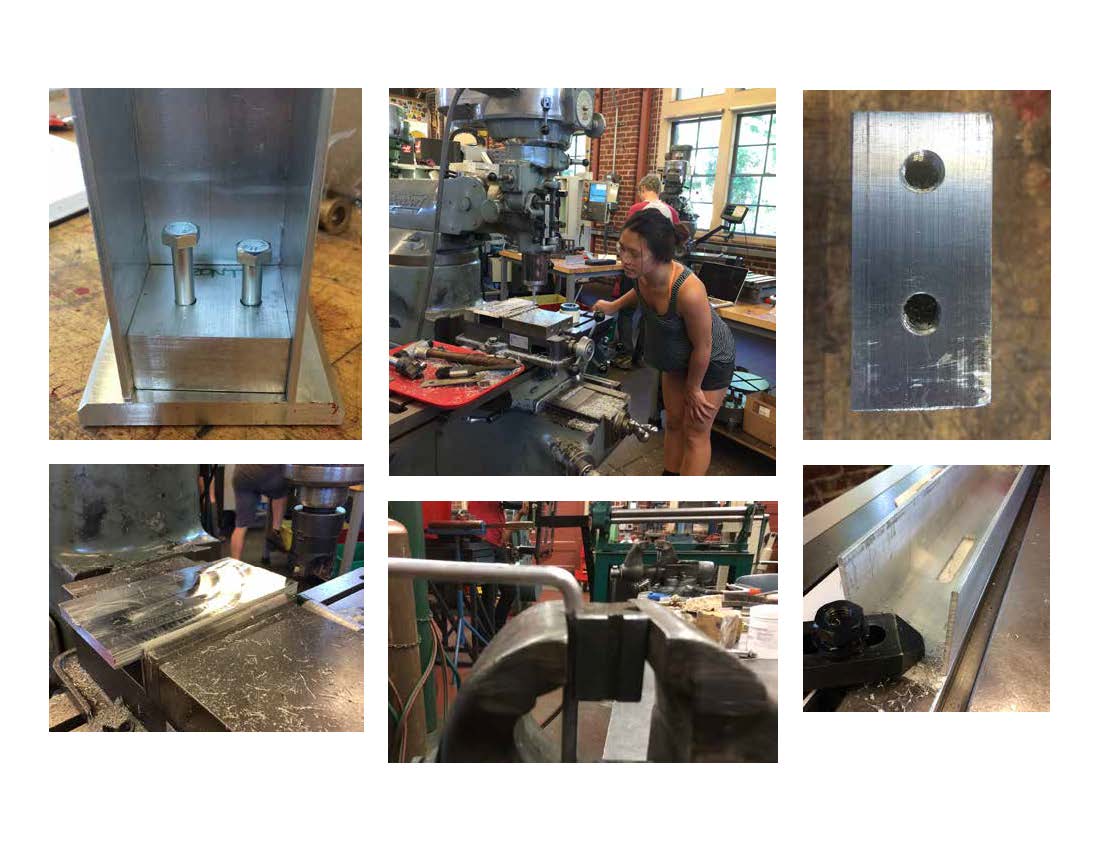

I designed and built a functional citrus juice press, with a cast reamer and squeezer, rack-and pinion press mechanism, and manually milled aluminum connections.

Approach/Methods:

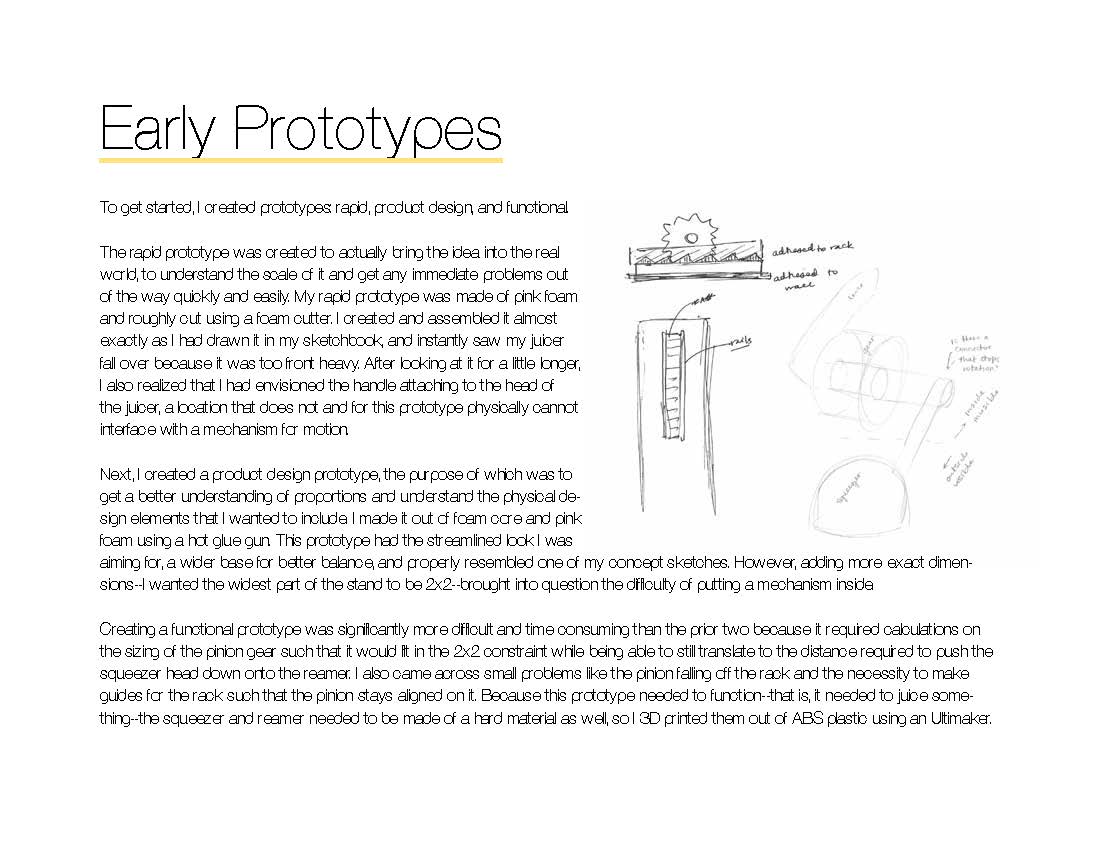

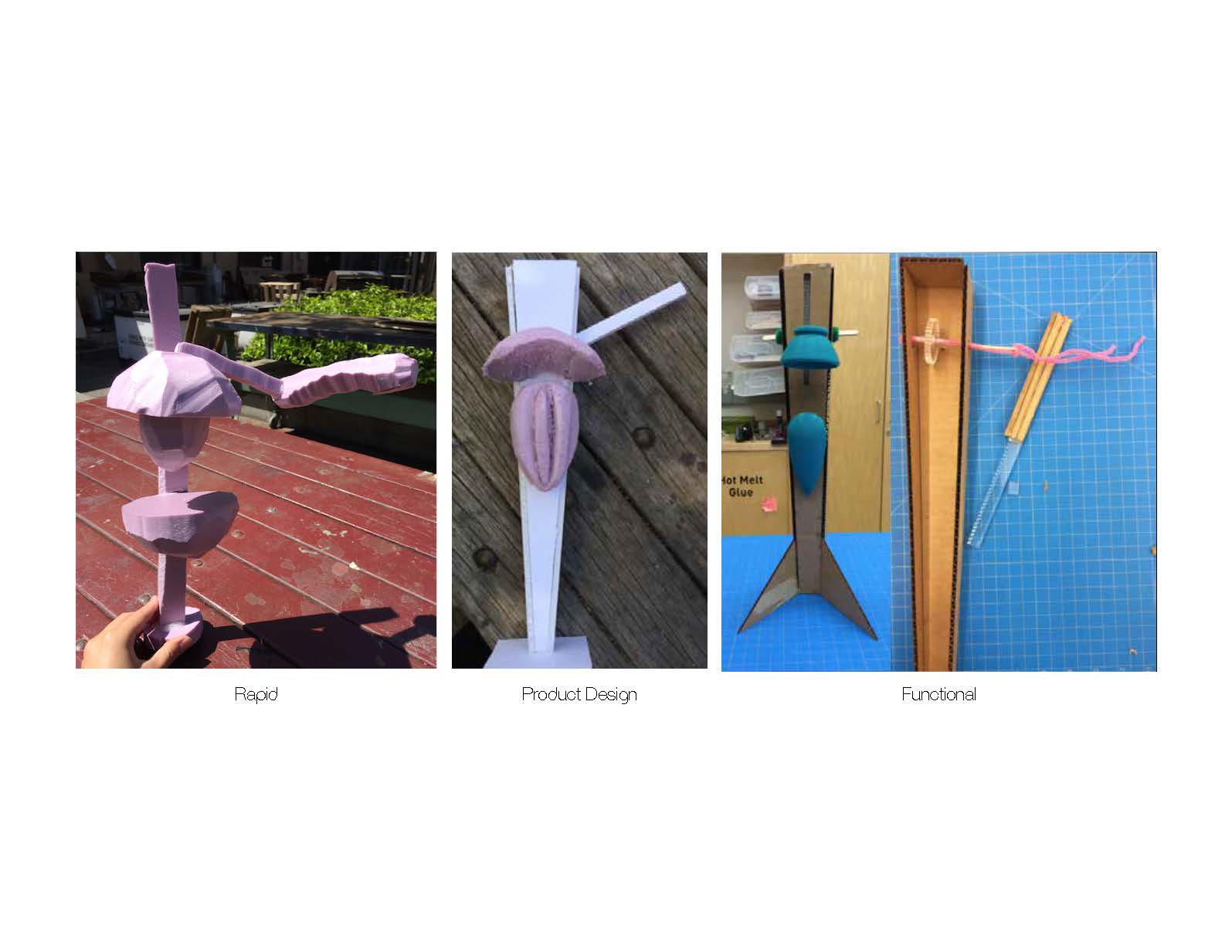

Low-fidelity prototyping: Pink foam, foam core, cardboard, hot glue, 3D printing

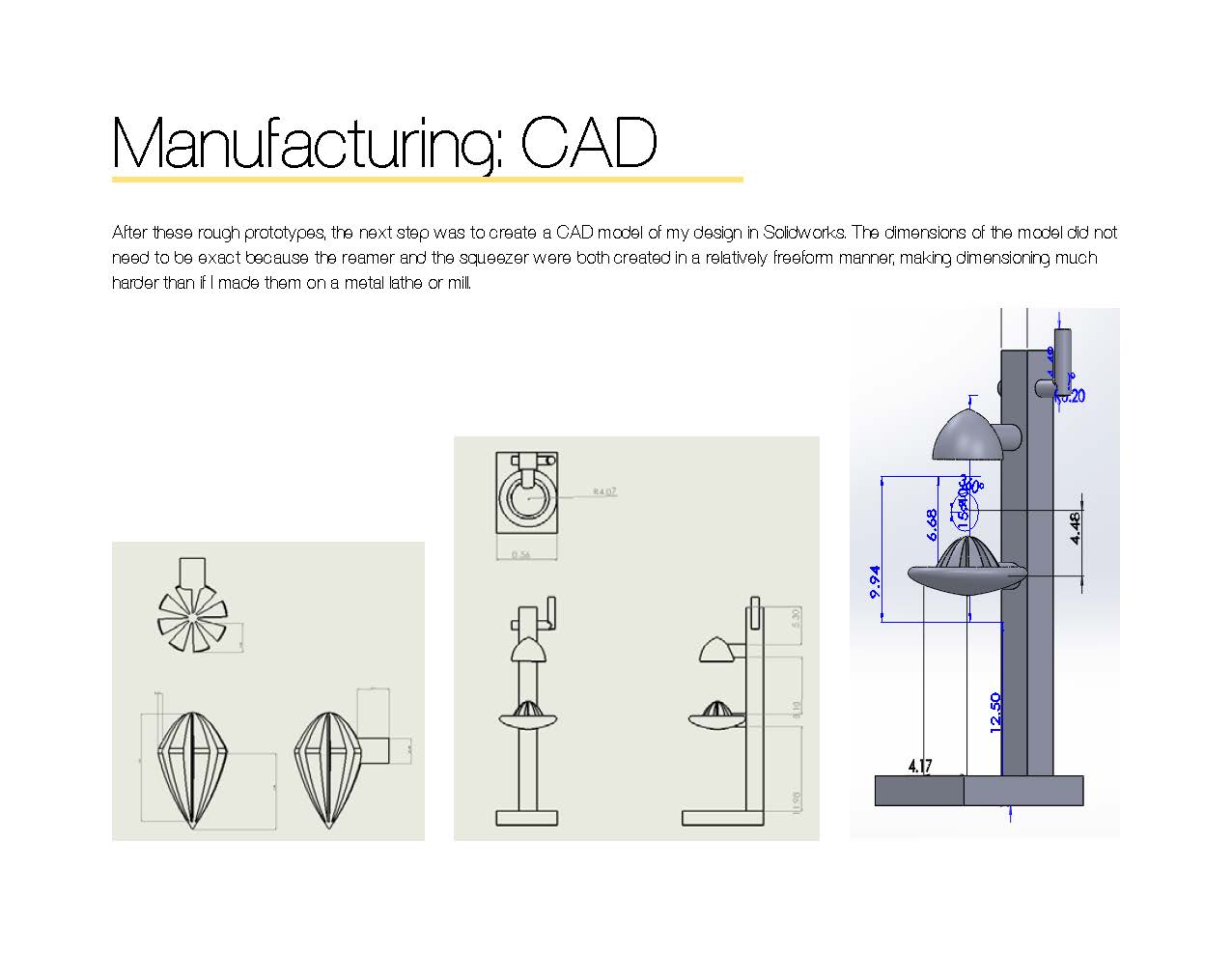

Solidworks: Rough CAD with key dimensions

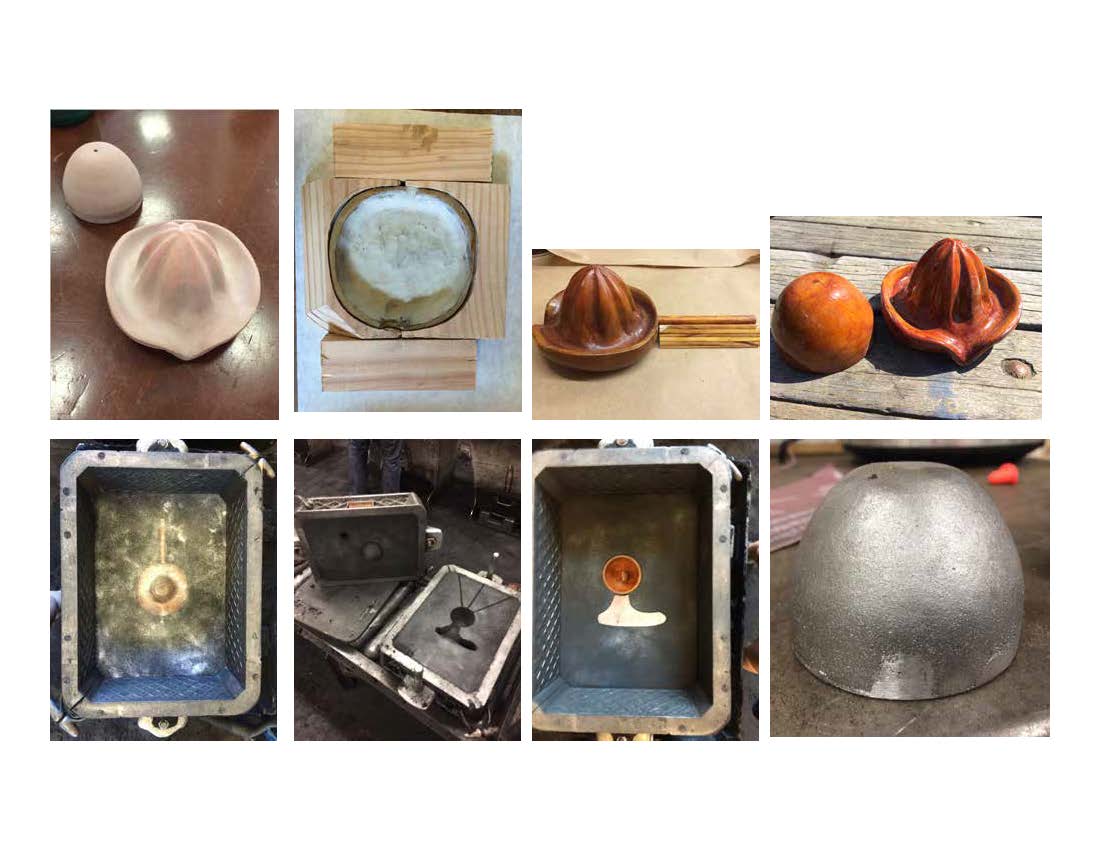

Sandcasting: Moldmaking (dremel, wood lathe) in modulan

Machine shop: Manual milling, hydraulic press

Highlights:

Ochre was my first foray into designing and building a multi-part object of my own creation, without any prompt but to make. I found it incredibly stressful but thrilling to face the complexities of bringing a concept to life. Now, after several years in industry, I recognize that the constraints of implementation are always more difficult than the initial ideation, and this experience was merely a compressed version of what I would find in the “real world.” It was an enlightening experience, and one that has shaped my thinking around product development in the years since.