Engineering

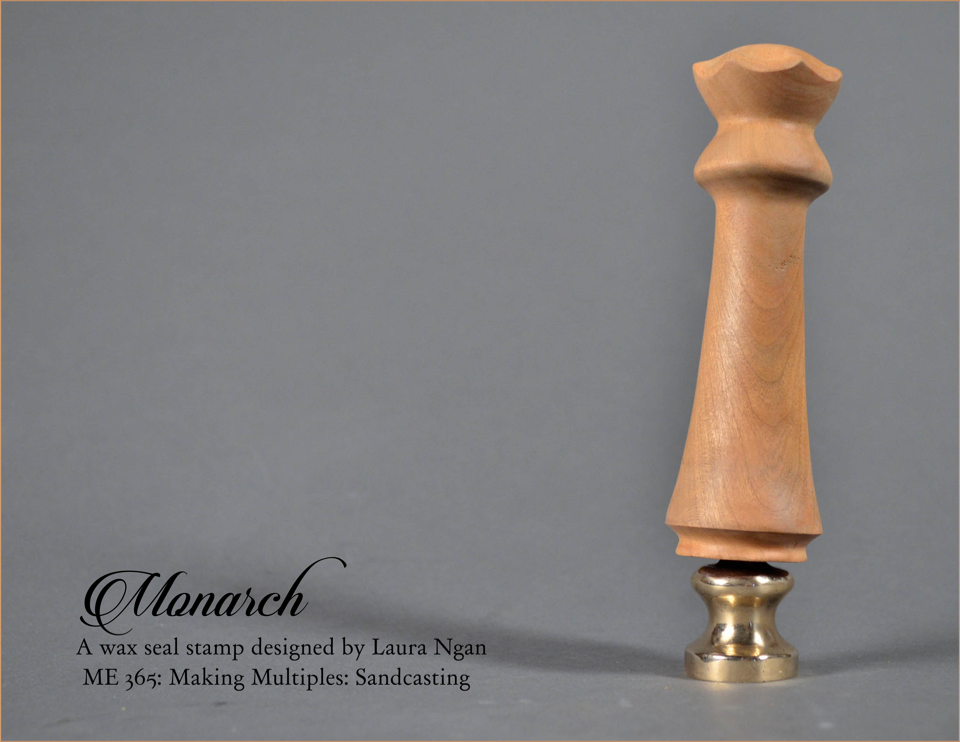

Monarch

A sand cast wax seal stamp

Problem Statement:

Design a sand cast piece incorporating movement and manufacturing scalability.

Project Details:

Individual project in a graduate-level sandcasting class (2018)

Objectives:

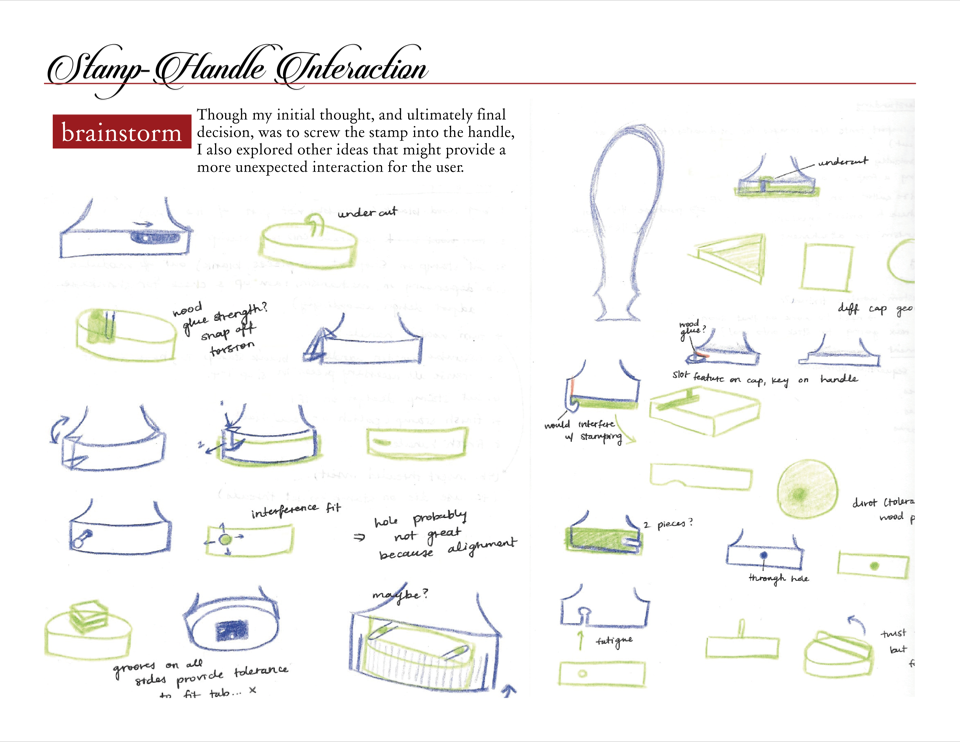

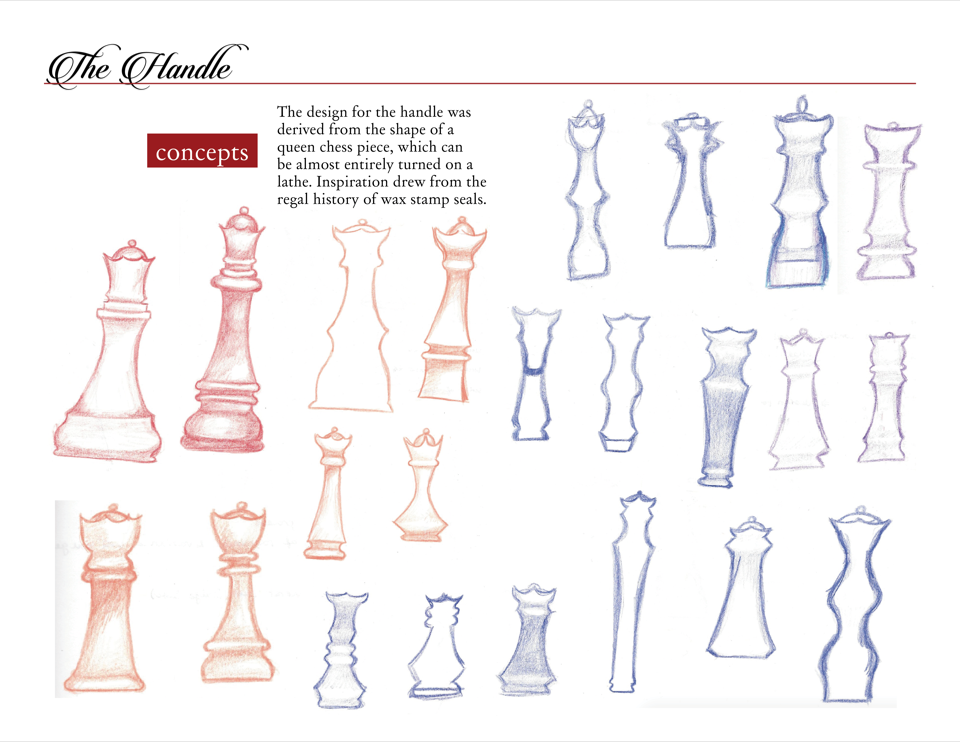

I chose to design and build a wax seal stamp that had a single handle but several stamp ends with the potential for numerous designs. The movement portion of the prompt was centered on the user pressing a puddle of molten wax into my design, an interaction that was delightful to both experience and witness during the final showcase.

Approach/Methods:

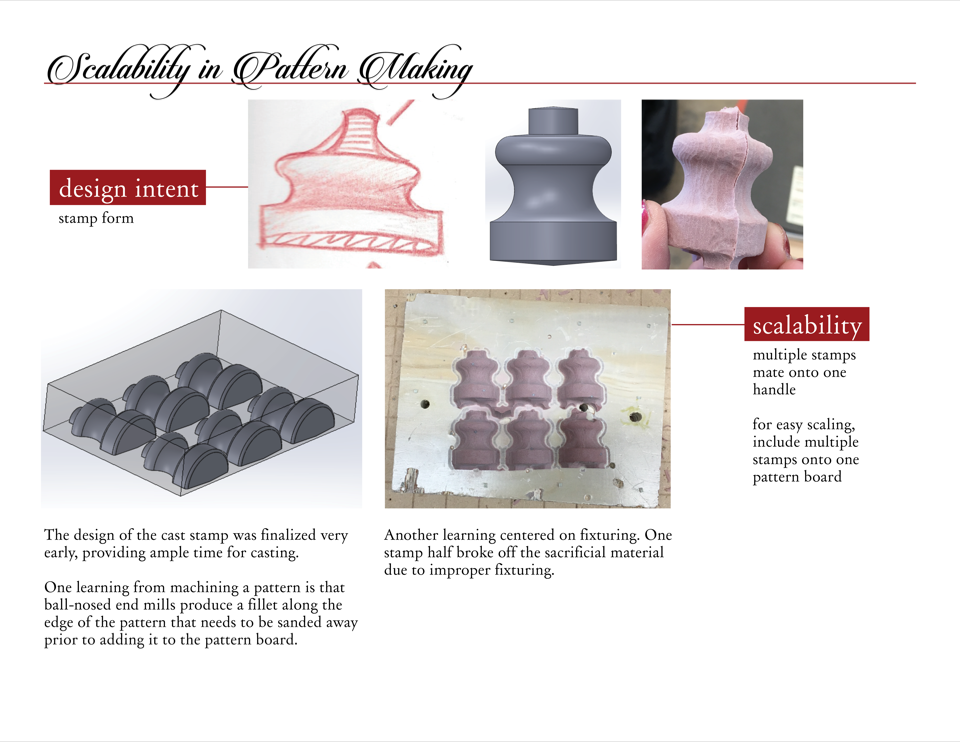

Ideation

CAD/CAM: Solidworks, HSMWorks

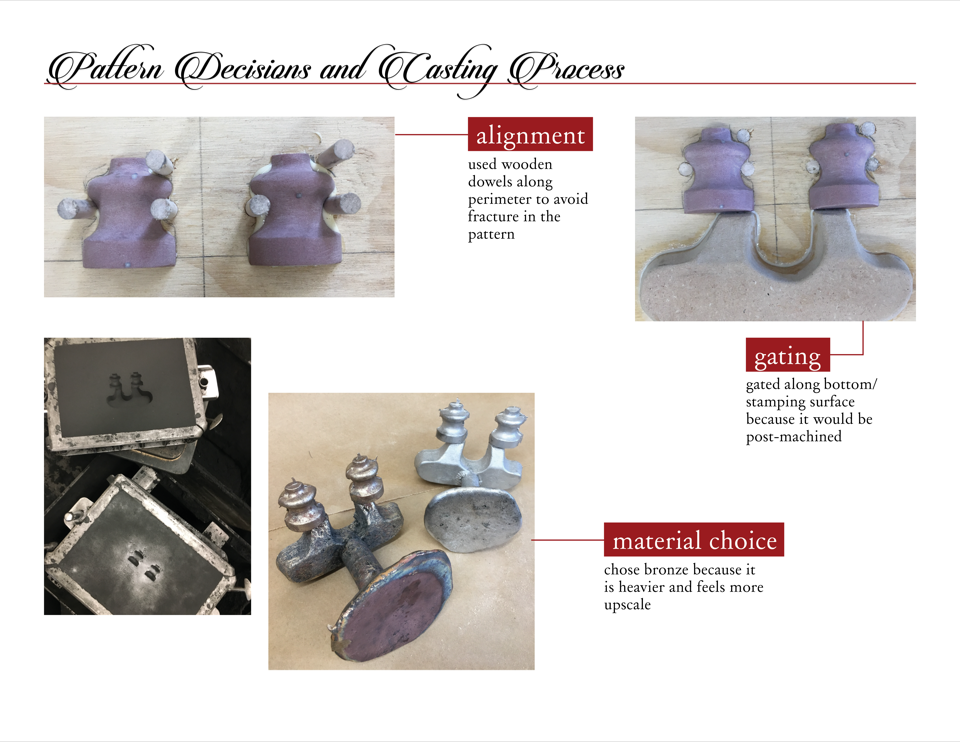

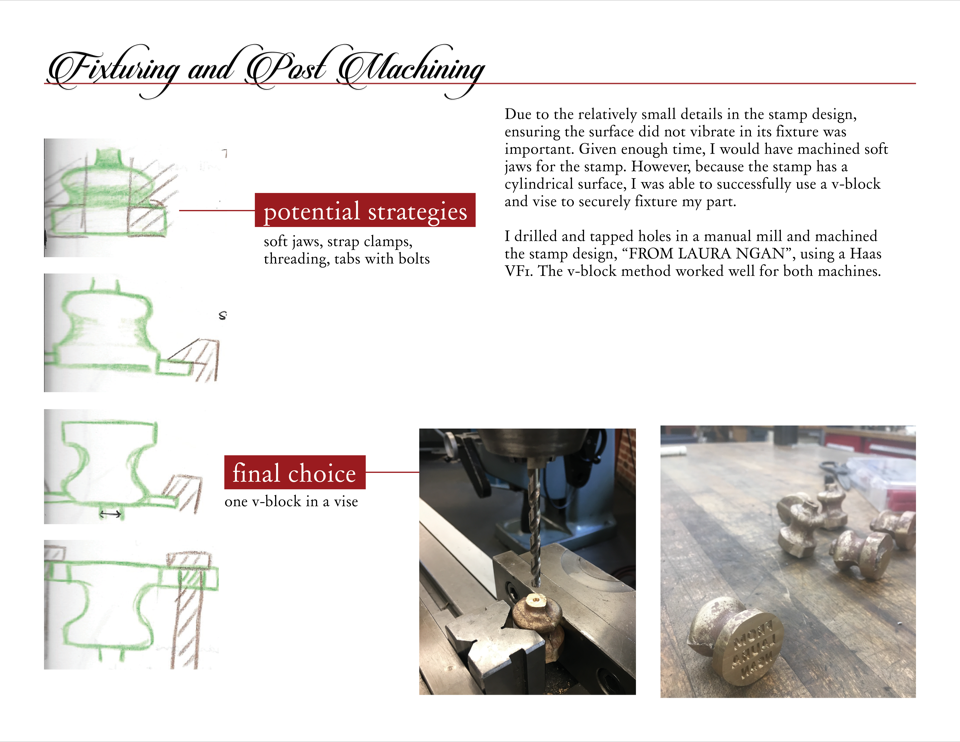

CNC: Shopbot router (modulan mold), Haas VF1 (post-machining)

Sand casting

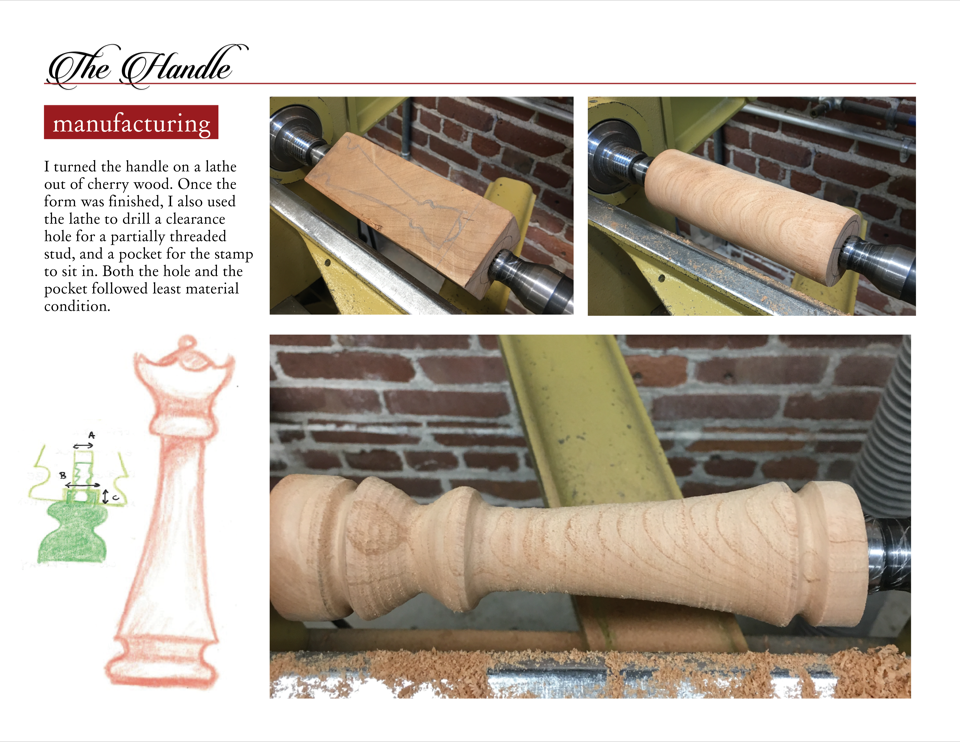

Wood lathe

Outcome:

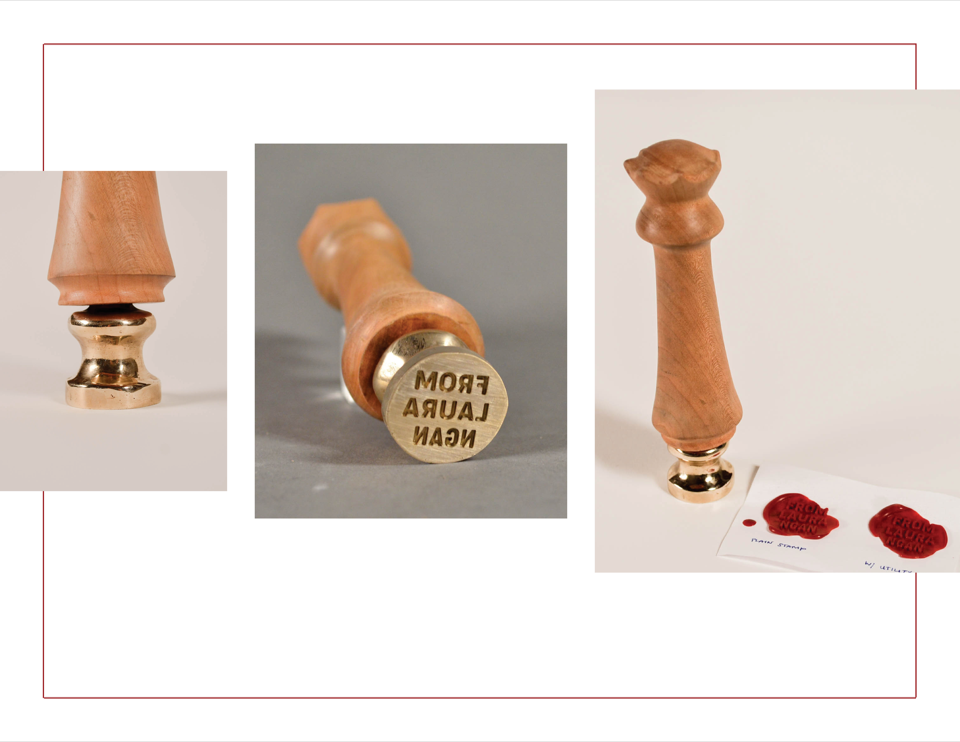

I designed and built a single turned wood handle that integrated with removable stamp ends. To facilitate scalability, I chose to include multiple stamp ends in a single pattern board, but I left them all blank during the casting process and post-machined them in a CNC afterwards so that the handle could be used modularly with several designs.

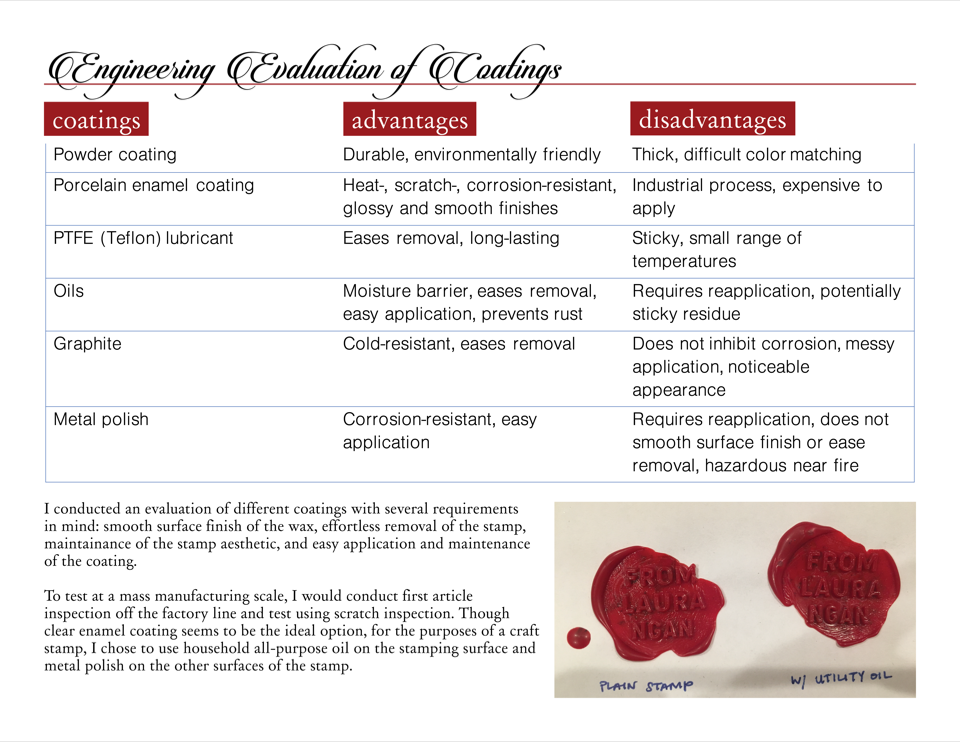

After completion of the physical stamp, I also conducted an analysis of a variety of coatings that might improve the surface finish of the seal.