Engineering

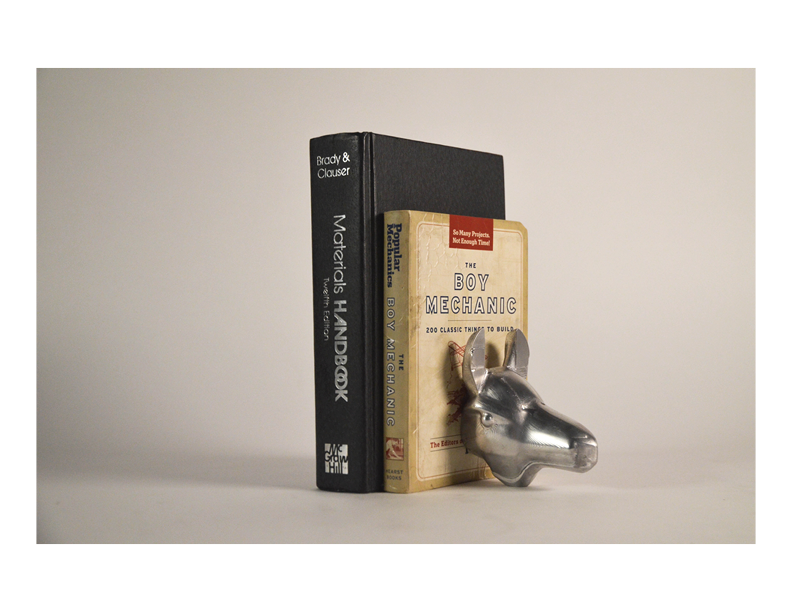

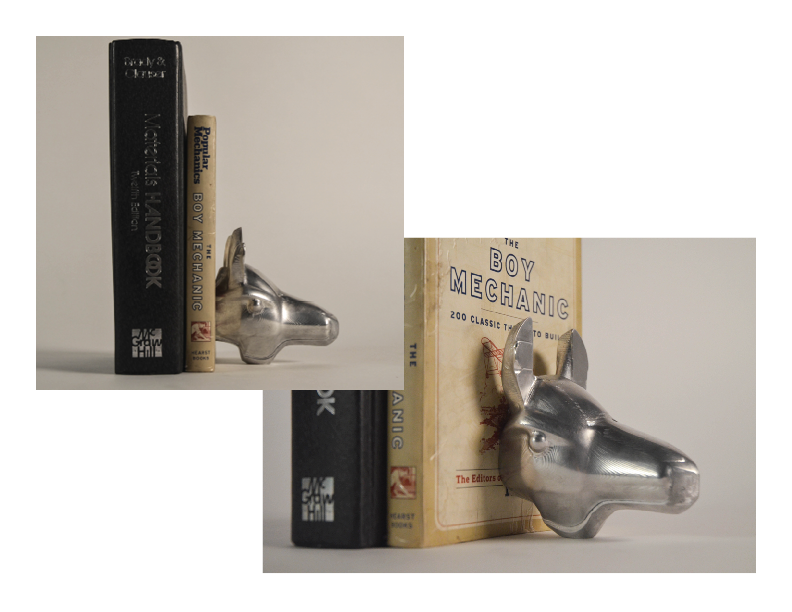

Wally the Llama

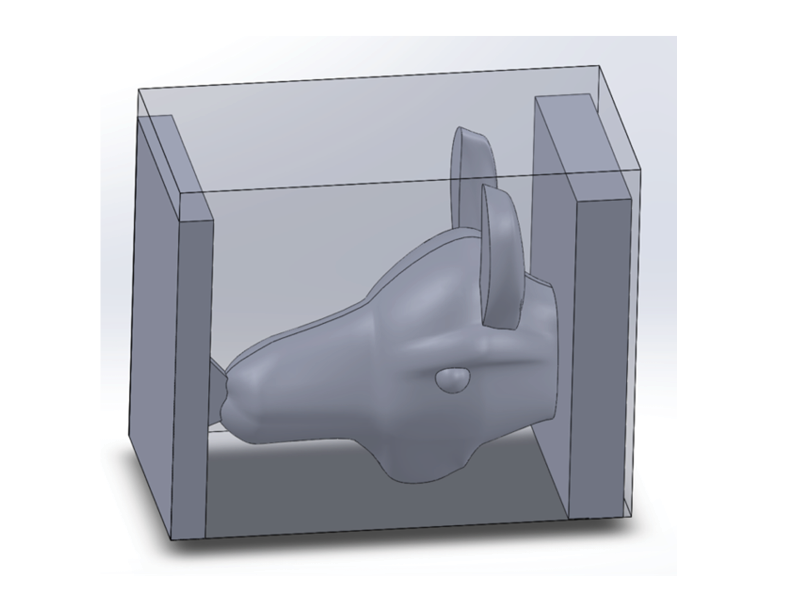

A CNC’ed llama-shaped bookend

Project Details:

Individual project in a graduate-level CNC milling class (2018)

Objectives:

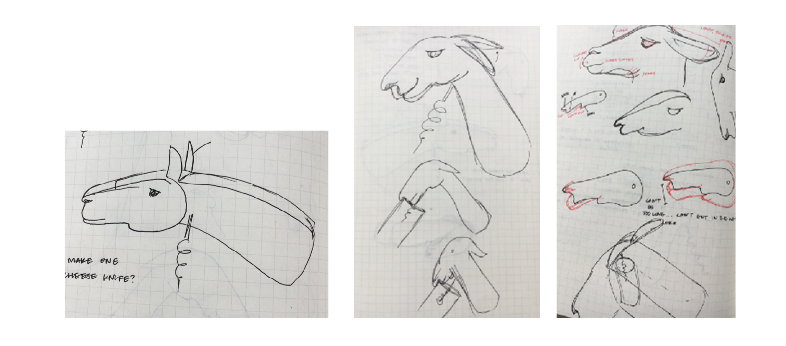

My initial intention for this project was to create a llama-shaped waiter’s key wine corkscrew, taking advantage of the geometry of a llama’s ears and head to play the roles of the foil cutter and levered handle respectively. However, ultimately, time constraints compounded with the complexity of the fixturing led me to shift to the bookend concept.

Approach/Methods:

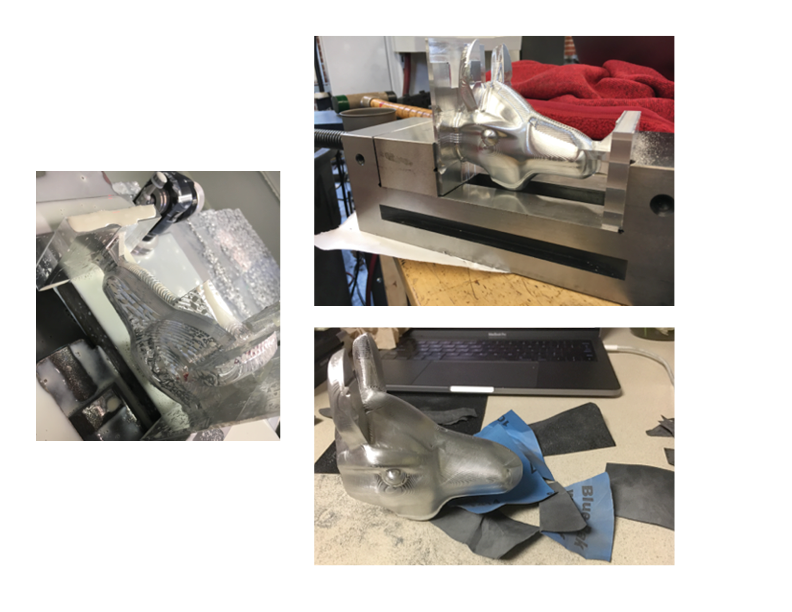

Iterative prototyping

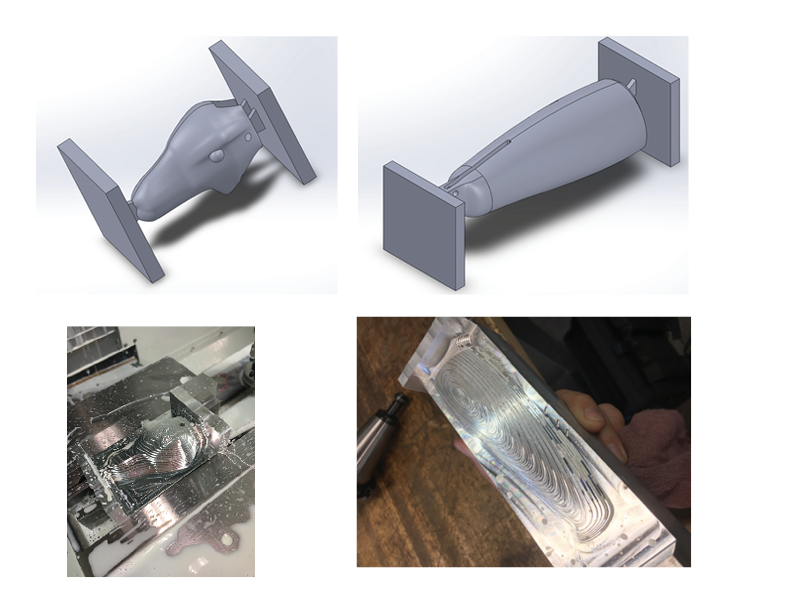

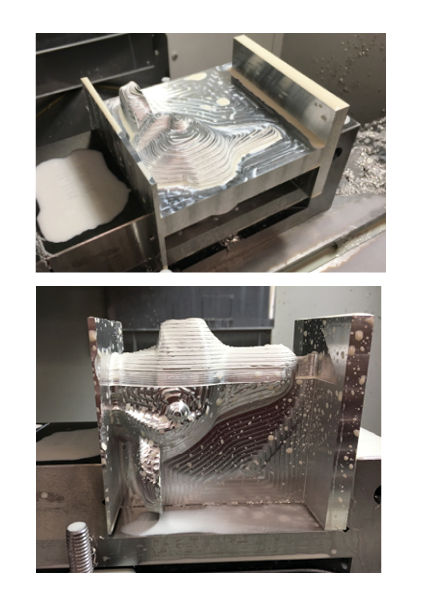

CNC: Fixturing, Haas VF1

CAD/CAM: Solidworks, HSMWorks

Highlights:

Because I was constrained to three axes in the machining process, the stock piece required four-turns in the vise to machine the full llama head and careful precision in edge-finding. The curvaceous geometry of the llama head is more suited to sand casting, rather than CNC milling, which is a lesson in pairing design intent with manufacturing method.